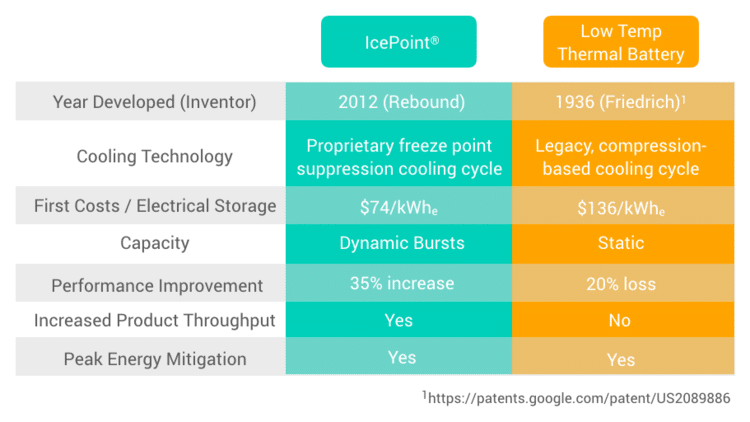

Very often Rebound is mistaken for a thermal battery, which I suppose is a reasonable misunderstanding seeing as we A) leverage ice generated during off-peak hours and B) can mitigate peak demand charges.

However, what we’ve actually developed is an entirely new high capacity cooling cycle, something that hasn’t been done since the early 20th century. [1] And its important to point out the distinctions. First though, some context.

In a sector with fairly trivial innovation, thermal battery development is one area that has gained a lot of attention over the last 10 years. With that attention has come improvements. What arguably started with Calmac almost four decades ago led to Ice Energy in 2003 and now Axiom Exergy in 2014. Companies like Buco, Baltimore Air Coil and Viking Thermal Solutions also have thermal battery products.

However, while these batteries add value mitigate peak energy expenses, they still leverage legacy, compression-based refrigeration equipment to produce the stored cooling capacity. And this is where Rebound and thermal batteries diverge.

Our team thrives on solving complex thermofluid challenges. One of the biggest, if not the biggest, challenges facing the refrigeration industry is how to develop a reliable, economically practical alternative to legacy, compression-based cooling. In developing IcePoint®, we indeed wanted to leverage ice storage, but our focus wasn’t isolated to shifting electricity purchases. Instead we set out to invent an entirely new cooling cycle, which is exactly what we are commercializing.

Rebound is currently operating the first commercially-deployed, closed loop, freeze point suppression cycle in the world. In fact, in the few days prior to publishing this article, 4200 lbs. of strawberries were frozen by IcePoint’s pilot system. So while words about IcePoint’s novelty might not mean much to the majority of readers, the primary take away is that this is the first step to reshaping how the world produces cooling.

The short, general comparison:

The longer, detailed comparison:

Materials

Thermal batteries use a single solution that goes through a freeze-thaw cycle, repetitively, to first store thermal energy and then utilize it. This single solution has a freeze point between -10°F and 10°F.

IcePoint® uses two different materials, which are mixed and then separated. The only material that is ever frozen is pure water, which has a freeze point of 32°F.

Efficiencies

Thermal batteries use legacy, compression-based equipment to freeze their mixture at temperatures as low as -10°F. This low temperature means the legacy equipment must work harder at an efficiency about 1.5-2X lower than if they were freezing their mixtures at 32°F. This, in combination with heat gains during the storage process, lead to a round trip efficiency comparable to other batteries of about 80%.

IcePoint® also uses legacy equipment to freeze its water, but at much higher efficiency because freezing occurs at 32°F. Due to the mixing step that leverages freeze point suppression and the separation step that leverages high efficiency nanofiltration, IcePoint® provides cooling at 35% greater efficiency.

Heat Exchange Surface Area

Most thermal batteries use ice-on-coil configurations meaning that there is a heat transfer fluid flowing through their mixture in tubes that both freeze the mixture and extract the energy from it for deployment. As a result there is a limit to the amount of energy that is transferred to the heat transfer fluid at any given time.

IcePoint® has hundreds of times more surface area available for heat transfer because the solid (ice) is stored in direct contact with it’s own heat transfer fluid (freeze point suppressant) that can be pumped at dynamic flow rates to the facility, allowing for the bursts of cooling that add such significant value. No other low temperature cooling technology in the world offers this functionality.

Cost & Economic Value

Using ice-on-coil requires either large copper heat exchangers or secondary glycol loops both of which increase the cost per kWh. Additionally, thermal batteries only mitigate peak energy expenses limiting their value generation.

On a per kWh provided, IcePoint® is 45% less expensive than a thermal battery. Additionally, IcePoint’s ability to supply bursts of cooling and subsequent acceleration of blast freezing cycles boosts revenues for facilities, providing an enormous value add unattainable by batteries.

—————————————-

[1] Lower capacity cycles like magnetic refrigeration, thermos-acoustic, hot electron and thermoelectric have been invented with only the latter of those seeing any traction.